Introduction

Tesla motors, is an electric car manufacturer, based in the Silicon Valley. It was created in 2003 by five founders: Martin Eberhard, Marc Tarpenning, Ian Wright, Elon Musk and JB Sraudel. The company was elected as the smartest company in the world (Byrnes, Nanette 2015), if the core of the company is the electric cars, Elon musk announced in April 2015, that the company plan to use the Tesla motors battery for home and industry. In this coursework, I will explain why Tesla motors is an innovative company, and how it will succeed in the lobby market of cars and fuel

Important information about Tesla Motors

Foundation date: 2003.

Current CEO: Elon Musk.

Current CTO: JB Straubel.

Slogan: The end of compromise.

Head quarter: Palo Alto, California, USA.

Numbers of employees: +6 000

Sale / Revenue: 3.2B £$ +58.85%

Share price: 232.68 $US

Top competitors: Ford Motor, General

Motors, Honda Motor Company, Tata

motors, Toyota Motor Corp

Motors, Honda Motor Company, Tata

motors, Toyota Motor Corp

Elon musk

He is the CEO of Tesla, pioneer in Electric cars in United State. CEO ofSpaceX, the goal of the company is to innovate in the rocket technology industry and to become a space-faring civilization, by using fully reusable rocket. And he’s the president of Solarcity, with high quality solar energy product.

Important fact:

Elon musk is one of the most significant actors in the digital revolution. And he is one of the richest man in the Silicon Valley with an estimated fortune of 11 billion dollars. He made his fortune with the purchase of

PayPal by EBay. And he invest practically all his fortune in technology

industry. The mindset of Elon Musk: Frugal Innovation. One of his secret is to cut all the price. According to his biography (Vance 2015) he gave a part to an engineer, and says that the market price for this part is 100 000$. He told him that he had to produce it for 5000$. Nine months later, the engineer produced that part for only 3900$.

PayPal by EBay. And he invest practically all his fortune in technology

industry. The mindset of Elon Musk: Frugal Innovation. One of his secret is to cut all the price. According to his biography (Vance 2015) he gave a part to an engineer, and says that the market price for this part is 100 000$. He told him that he had to produce it for 5000$. Nine months later, the engineer produced that part for only 3900$.

“Failure is an option here. If things are not failing, you are not innovating enough” - Elon Musk

The vision

Innovation in a real strength nowadays, if you want to be different from your competitors. The car market, is one of the most difficult market to penetrate because of big company that’s are here from decades for example Mercedes or Ford. It is very primordial for a company who want to penetrate the car industry. This is a real challenge, and Elon Musk and Tesla Motors will handle it. The first sustainable Electrics vehicle with a range of 265 miles (Roadster model). This is more than twice of competitors (BMW, Nissan, and Tata). And a recharge time of thirty minutes due

to a high technology battery. And Tesla is the first company that will be able to produce a mass market for Electrics vehicle with the Giga Factory. A 10 million square meters factory in the middle of Nevada, with high technology robot, able to produce 500 000 cars a year, and can produce the battery needs of the world for one year

to a high technology battery. And Tesla is the first company that will be able to produce a mass market for Electrics vehicle with the Giga Factory. A 10 million square meters factory in the middle of Nevada, with high technology robot, able to produce 500 000 cars a year, and can produce the battery needs of the world for one year

Corporate strategy

According to Elon Musk during a Tedtalk in 2013, the strategy of Tesla can be summarize in three steps. The first step is to launch a high technological car, with an expensive price to establish a basement. But with a low volume, to respect the principle of rarity, one of the keystone of Jugaad. This first step was the “Roadster”, a sport car with a price of 100.000$. The step two, is to launch an affordable car for the upper-middle class, with a medium volume of

production. The name of the car is the “Model S“, and the price is about 50.000$. And for the third step, Tesla plan to launch it due to the Gigafactory, the economy of scale (Truett 2015), technological advances that will cut battery costs by 30%. The “Model X”, an affordable car for the mainstream market, with a price of 30.000$. This strategy is innovative, because tesla penetrate market from above. The company play on rarity and luxe to create the need.

production. The name of the car is the “Model S“, and the price is about 50.000$. And for the third step, Tesla plan to launch it due to the Gigafactory, the economy of scale (Truett 2015), technological advances that will cut battery costs by 30%. The “Model X”, an affordable car for the mainstream market, with a price of 30.000$. This strategy is innovative, because tesla penetrate market from above. The company play on rarity and luxe to create the need.

Innovative progress

Constant innovation process

This is the only way to challenge the automotive industry, a great example of innovation of tesla is about their production department and how they use the lean start-up method. Big automotive company have a big production site, that never change, that is not update with the change to minimize the cost. At Tesla motors, production engineers always change the factory organization to adapt.

They try to stay the most agile as possible, due to evolution of needs. And also because tesla have a big challenge, they need to reduce the cost of production of their cars. They need to optimize the production chain all the time. Principle of do more with less (Partha sarathi 2012)

Network and speed

One of the principle of Tesla is the speed. All employees include Elon musk are working more than 90 hours a week. It allow the company to react very fast when facing a problem of production or a software problem. The car is developing with a lot of hardware but also with a huge software part. This why the car is such a luxury product. The software is directly include into the car. All the update are made during the night. This software also allow the company to gather a lot of feedbacks from customers. For example, a lot of customers complain about the

comfort of the “model S” seat. Few months later, Tesla motors redesign and change all the seats of all the Tesla car on the market, for free. This a good example of speed that is keys element to face as a company currently according to Jim Snave SAP Co-CEO (Silicon 2013). They are also facing to the interconnection key element, they use the new technology of digital as a real strengths. First, they use their software to gather feedback, allow them to adapt to the need and react very fast go along with a very agile method (Aubry 2013) in a very uncertain market. In another hand they also use it to upgrade their product in an easy way. If other cars never evolve when they are out of the shop. The tesla’s car evolve all the time due to this system. Tesla update wirelessly their vehicle to install better and safer version of their software. Once, they had a problem concerning the software, they use the 4G connexion to install a new version during the night, at the same time General Motors as a similar problem of their software. They had to recall 370.00 cars into a dealership. But, if we considers that the number of sold of cars will increase for the future (500.000 in 2017/2020), the 4G Network will not be enough to handle big maintenance for the Software.

In any event with this current setup. Tesla may have an answer to this problem. If not, they will be force to build an after-sales service network to handle this problem.

comfort of the “model S” seat. Few months later, Tesla motors redesign and change all the seats of all the Tesla car on the market, for free. This a good example of speed that is keys element to face as a company currently according to Jim Snave SAP Co-CEO (Silicon 2013). They are also facing to the interconnection key element, they use the new technology of digital as a real strengths. First, they use their software to gather feedback, allow them to adapt to the need and react very fast go along with a very agile method (Aubry 2013) in a very uncertain market. In another hand they also use it to upgrade their product in an easy way. If other cars never evolve when they are out of the shop. The tesla’s car evolve all the time due to this system. Tesla update wirelessly their vehicle to install better and safer version of their software. Once, they had a problem concerning the software, they use the 4G connexion to install a new version during the night, at the same time General Motors as a similar problem of their software. They had to recall 370.00 cars into a dealership. But, if we considers that the number of sold of cars will increase for the future (500.000 in 2017/2020), the 4G Network will not be enough to handle big maintenance for the Software.

In any event with this current setup. Tesla may have an answer to this problem. If not, they will be force to build an after-sales service network to handle this problem.

The 14th October morning, all the users of Tesla’s “Model S” had a surprise, in fact, during the night, Tesla Motors launch a new update. The automatic pilot. The cars made the update alone using a 4G system to download and install it with the Tesla Software. If the automatic pilot is an impressive technology innovation, the company know how to use digital and use it well. According to Charles Delaville, French spokesperson of Tesla Motors, the company develop the car and the software in the same way as we develop a smartphone. User-friendly, easy to use,

and intelligen

and intelligen

Seek opportunity in adversity

The automobile industry in a very difficult market for new entrants (Stringham 2015). Because of necessity of a high capital for the entry cost but also because the company have to be able to produce very large amount of product very fast. They are a lot of barriers that is very difficult to overcome. But Tesla with a logic a partnership and a very high market capitalization (Half of General Motors) has shown, that it’s possible. In February, Tesla motors just raised 1.6 billion dollars in capital to accelerate the growth of the market and assume a mass market production. The money will be invest in the construction of the GigaFactory. (Solomon 2015) Tesla motors know that the automobile market is difficult to penetrate, but with an innovative product and a smart strategy, they make the impossible.

Manufacturing differently

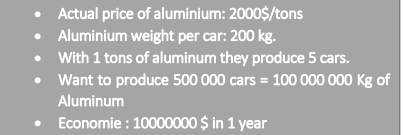

The company chose to change how an automobile industry produce cars. Indeed they inspired of the technology company for example, the way how Apple produce the IPad. They use EMS, for Electronic manufacturing services model of production. According to HIS, looking into a “Model S” is like looking into the new IPhone or the new Samsung Galaxy. Automaker like General Motor generally purchase the electronics system to a provider like

Panasonic, and concentrate the production in the real part of the cars like doors, bonnet. But at Tesla, most of the electronics product like the huge screen on the dashboard have the label Tesla Motors. But they also produce their own electric motor, gearbox and car body in Aluminium.

Panasonic, and concentrate the production in the real part of the cars like doors, bonnet. But at Tesla, most of the electronics product like the huge screen on the dashboard have the label Tesla Motors. But they also produce their own electric motor, gearbox and car body in Aluminium.

Cross fertilize idea

As we observe previously, Elon Musk is also the owner of SpaceX, Aerospatiale Company.

Something that is very interesting, is that he uses some Aerospatiale technology in the Tesla

motors manufacturing process. Indeed, Tesla is benefiting from the sharing technologies, the

friction stir welding.

Something that is very interesting, is that he uses some Aerospatiale technology in the Tesla

motors manufacturing process. Indeed, Tesla is benefiting from the sharing technologies, the

friction stir welding.

« Instead of riveting the ribs and hoops, you use a special machine that softens the metal onboth sides of the joint without penetrating it or melting it. Unlike traditional welding, which melts and potentially compromises some metals, this process works well with high-strength aluminium alloys. You wind up with a stiffer, lighter structure than was possible before. And your material loss is maybe 10 percent, just for trimming the edges. »

-Elon musk

Tesla Motors use this technology in several part of the “Model S” like the chassis and the body that are in aluminium. This is a real key for the car, because it allow the company to produce a car safer and above all a lighter vehicle. So the company can gain a better battery efficiency and so a better range. And also, always in a logic of frugal innovation, to reduce the loss of raw materials.

Human resources organization

One thing that can characterize Tesla, is that they don’t recruit people about their experiences. They don’t believe in this kind of standard recruitment. During an interview, they expose people to very complex problem, and see if they can solve it, easily, at lower cost and explain it in a very simple way. Vijayan is the CIO of Tesla Motors, when he was hired at Tesla Motors, is first major task was to build all the software to run the business. He has 3 constraints: Built it from scratch, in three months, for one-fifths of the cost. Vijayan told Musk such a task wasn’t possible, Musk simply answer that if he needs help, he must contact him. (Dyer, Gregersen, Nathan 2015). Vijayan manage to complete the task in 4 months.At Tesla Motors, people are functioning in small team, with very low budget, but with a very high potential of intern communication. That allow the team to move on very fast in a project. For example, the “Model S”, awarding of design award, was designed by 3 designer’s seat side by side of engineers. This set up, allow the team to communicate rapidly about design and possibility of construction with the constraints of the battery, weight, raw materials, aero dynamism.

Innovative technology

Battery system

After twenty years of research & development, Tesla Motors manage to reinvent the concept of EV. With a smart engineering of pack battery, it’s allow a good acceleration, safety (Reduce the risk of fire in tangible way) and power. They select thousands of Ion-Lithium cell from the top quality, and pack them in a liquid cooling and coated in a solid packaging. And all of this packaging is recyclable at 60%, with a goal of 90% in the future (my.teslamotors.com 2015), in scope of their environment logic.

Supercharge station

This station really make the difference from other EV automaker. Tesla Motors is the only automaker that provide charge station all around the world. According to Elon musk, you can cross all the United States with a Tesla Motors car. The supercharger are free charger station (Customers can find it via Tesla App or via Google map) that charge the battery of the car in few minutes (30 minutes charging= 273 km). Customers have the time to eat at a restaurant eat a quick lunch, check their mobile to see if the car is ready (Teslamotors 2015).

The battery is the principal aspect that check a customers when he wants to buy an EV. And this is the main problem of customers, “How I will recharge my car? “, “Where I will find station to charge it?”, “How long will it take to get charge?”

And Tesla knows this problem. This is why they answer to this problematic with a high quality battery that offer the best range on the market, and offer one of the best charging time battery on the market (Main competitor : Storedot, that offer 1 minute charge for 100km, and working on a project of charging road ).If Tesla’s planning to install more and more supercharger station in the world, they have a lot of work to cover the entire world, and this is one of their challenge to conquer the market. For example, from Coventry, the first supercharger station is about 30 minutes (35.5Km)

Robots factory

The Tesla motors factory is known as the most advanced factory in the world due to high technological robots on the production line. The company own more than 160 robots for 3000 employees. According to the Tesla blog, they upgraded the whole factory in November 2014 (Tesla Motors 2014), in the logic of lean start-up, they’ve eliminated all the waste, and optimize production, quality and time. They replace all overhead steel and mechanical structure for robots. Robots are all along the production line and do different tasks as lift, pre-treatment, pre coat, base coat, install the seat, the door or even the wind screen. We also can find the robot “Smart car “that moving car by itself following a black line of floor.

The factory of Tesla is the contrary of Ford and the logic of Fordism. Robot can do several task and work all together to produce a car. Eight robots can work simultaneously, and Tesla motors can produce different model of car on the same production line.

Marketing critics

As we observe earlier, with the GigaFactory and the third cars of tesla, “Model X”, that Tesla Motors target a mass market (Goal: 500 000 cars in 2020). The previous cars like “Roadster” or “Model S” were created to seduce Rich Early adopters. But according to HIS, Tesla would have a problem: Can it be scaled up to meet its sales target?

According to IHS, 51.8% of all tesla buyers earn more than 150.000$ a year. And if we compare those numbers with the Chevrolet’s buyer, we observe that buyers with an income of 150.000$ a year only represent 6.5% of the buyers. Indeed, Tesla will need to create a marketing strategy to reach the good target: Economy-car- customers. If the Tesla want to spread the hype around is product, it’s will be a necessities.

According to IHS, 51.8% of all tesla buyers earn more than 150.000$ a year. And if we compare those numbers with the Chevrolet’s buyer, we observe that buyers with an income of 150.000$ a year only represent 6.5% of the buyers. Indeed, Tesla will need to create a marketing strategy to reach the good target: Economy-car- customers. If the Tesla want to spread the hype around is product, it’s will be a necessities.

Thank you for reading this article. Please don't hesitate to leave a comment. I would love to read your opinion.

Referencing

Aubry,C. (2015) Le guide pratique de la méthode agile la plus populaire. Edition Dunod.

Byrnes, Nanette. (2015) « Business enterprises – Ratings & rankings ». MIT

Technology Review [online] Vol 118 (4), 45-47. Available from

<http://http://www.technologyreview.com/lists/companies/2015/> [08/11/2015]

Dyer,J., Gregersen,H., Furr,N.(2015) “Tesla”s secret formula”. Forbes Vol.196, 90-118

Goldstein, B., Rodriguez, D. (2012) “Turning adversity into opportunity-

Entrepreneurship and the information professional”. Information Services & Use

Entrepreneurship and the information professional”. Information Services & Use

[Online] Vol.32, 175-179. available from

<http://web.b.ebscohost.com/ehost/detail/detail?sid=9964c1dc-e548-49f5-8fcf-

9e8d801da6f8%40sessionmgr113&vid=0&hid=130&bdata=JnNpdGU9ZWhvc3QtbGl

2ZQ%3d%3d#db=a9h&AN=84931384> [08/11/2015]

Jim Snave, SAP : “ La vitesse d’innovation est le sujet majeur “ (2013) Silicon [online]

available from <http://www.silicon.fr/jim-snabe-sap-vitesse-innovation-

90869.html>[08/11/2015]

My Tesla motors (n. d.) “Batterie” [online] available from

<http://my.teslamotors.com/fr_CH/roadster/technology/battery> [09/11/2015]

Partha Sarathi,R. (2012) “JUGAAD Innovation”. The Journal for Decision Makers

[online] Vol. 37 (3), 162-164 available from

<http://web.b.ebscohost.com/ehost/pdfviewer/pdfviewer?sid=655c99a7-c2e5-4916-

8a6d-09998dfd1b1e%40sessionmgr114&vid=2&hid=130> [08/11/2015]

Press IHS (2014) “Is it a Car or an Ipad” [online] available from

<http://press.ihs.com/press-release/automotive/it-car-or-ipad> [08/11/2015]

Solomon,B. (2014) “Tesla raising $1.6 Billion for “Gigafactory” and Next Gen Vehicles”. Forbes [online], 18-18. Available from <http://www.forbes.com/sites/briansolomon/2014/02/26/tesla-raising-1-6-billion-for-

gigafactory-and-next-gen-vehicles/> [08/11/2015]

gigafactory-and-next-gen-vehicles/> [08/11/2015]

Stringham, E P “Overcoming barriers to entry in an Estabilished Industry: TESLA MOTORS” California Management Review [online], Vol.57, 85-103. Available from <http://web.b.ebscohost.com/ehost/detail/detail?sid=9c0ec5c3-b4d1-472a-8809 9c469faf1cdb%40sessionmgr111&vid=0&hid=130&bdata=JnNpdGU9ZWhvc3QtbGl2ZQ%3d%3d#AN=109928656&db=bth> [08/11/2015]

Tesla motors (5 November 2014) “Blog Factory upgrade” [online] available from <http://www.teslamotors.com/blog/factory-upgrade> [09/11/2015]

Tesla motors (n. d.) “Supercharger” [online] available from <http://www.teslamotors.com/en_GB/supercharger?redirect=no> [09/11/2015]

Truett,R. (2015) “LG Chem exec: Tesla’s Gigafactory to cut EV costs”. Automotive News Vol.89, p0024-0024

Vance,A. (2015) Elon Musk- Tesla, SpaceX and the Quest for a fantastic Future. Ed Ecco